- Description

Standards compliance

|

|

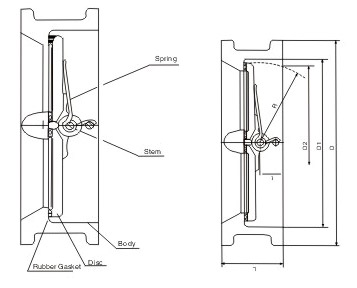

- Product introduction

The wafer flange clamped butterfly check valve is a energy-save produt. It is manufactured based the foreign advancec technology and in accordance with relative international standards. This product is featured by excellent retaining per-formance high safety and reliability and low flow resistance. It is suitable for systems in the industries of petrochemical food processing medicine,textile,paper-making. Water,supply,drainage,metallurgy,energy and light industry,etc,used as a check valve in one way.

- Features

- Small in size,light in weight,compact in structure,easy in maintenance.

- Two torsion springs are used exerting on each of the pair valve plates.Which close the plates quickly and automatically.

- The quick-close action prevents the medium from flowing back and eliminates water-hammer effect.

- This valve is short in length,so that it is laid horizontally or vertically.

- It is easy to install on pipeline which is laid horizontally or vertically.

- This valve is tightly sealed without leakage under the pressure water test.

- Safe and reliable in operation,high interference-resistance.

- The connection dimensions of flanges accord with the standards of GB4216-84 GB4216.5-84

- The face to face dimensions are in accordance with GB12221-89.ISO 5752-82. The stem of the valve should be perpendicular to the horizontal level when the valve is mounted on horizontal pipeline.For vertical installation the direction of flow should be downward.

CLASS 150~CLASS 300 Butterfly swing check valve

- Materials for main parts

| Part | WCB | A352LCB | A217 WC 6 | A217 WC9 | A217 C 5 | A217 C 12 | A351 CF 8 | A351 CF 8M |

| Body | A216 WCB | A352LCB | A217 WC 6 | A217 WC 9 | A217 C 5 | A217 C 12 | A351 CF 8 | A351 CF 8M |

| Disc | A351 CF 8 | A351 CF 8 | A182 F 11 | A182 F 22 | A217 C 5 | A217 C 12 | A182 F 304 | A182 F 316 |

| Stem | A182 F 304 | A182 F 304 | A182 F304 | A182 F304 | A182 F304 | A182 F304 | A182 F304 | A182 F316 |

| Spring | Stainless steel | |||||||

| Rubber Gasket | EPDM-46-+121 Neoprene-50-+150 NBR-35-+113 Fluororabber-23-+150 |

|||||||

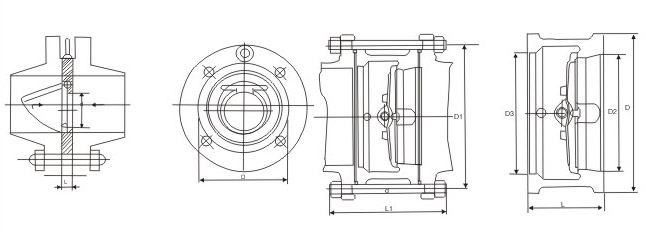

- Moverall & structure dimension & weight

| Size | D | D1 | D2 | L | R | t | Weight (kg) |

|

| mm | inch | |||||||

| 50 | 2" | 107 | 65 | 43.3 | 43 | 28.8 | 19 | 1.5 |

| 65 | 2.5" | 127 | 800 | 60.2 | 46 | 36.1 | 20 | 2.4 |

| 80 | 3" | 142 | 94 | 66.4 | 64 | 43.4 | 28 | 3.6 |

| 100 | 4'` | 162 | 117 | 90.8 | 64 | 52.8 | 27 | 5.7 |

| 125 | 5" | 192 | 145 | 116.9 | 70 | 65.7 | 30 | 7.3 |

| 150 | 6" | 213 | 170 | 144.6 | 76 | 78.6 | 31 | 9.0 |

| 200 | 8" | 273 | 224 | 198.2 | 89 | 104.4 | 33 | 17 |

| 250 | 10" | 323 | 265 | 233.7 | 114 | 127 | 50 | 26 |

| 300 | 12" | 378 | 310 | 283.9 | 114 | 148.3 | 43 | 42 |

| 350 | 14" | 438 | 360 | 332.9 | 127 | 172.4 | 46 | 55 |

| 400 | 16" | 439 | 410 | 381.0 | 140 | 197.4 | 52 | 75 |

| 450 | 18" | 555 | 450 | 419.9 | 152 | 217.8 | 58 | 101(107) |

| 500 | 20" | 594 | 505 | 467.8 | 152 | 241 | 58 | 111 |

| 600 | 24" | 690 | 624 | 572.6 | 178 | 295.4 | 73 | 172 |

| 700 | 28" | 800 | 720 | 680 | 29 | 354 | 98 | 219 |

Stainless steel on the folder-type check valve (H74W)30 4

- Performance parameters

| Type | PN(MPa) | Pressure test Ps(MPa) | Appropriate temperature(ºC) | Apprropriate medium | |

| Shell | Seal | Hard Seal | |||

| H74 | 1.0 | 1.50 | 1.10 | ≤400 | Oil,water,acid Alkali |

| H74 | 1.6 | 2.40 | 1.76 | ||

| H74 | 2.5 | 3.75 | 2.75 | ||

| H74 | 4.0 | 6.00 | 4.40 | ||

- Main size

| DN(mm) | L | D | |||||

| D | I | II | PN1.0 | PN1.6 | PN2.5 | PN4.0 | |

| 50 | 27 | 15 | 22 | 107 | 107 | 109 | 109 |

| 65 | 39 | 15 | 22 | 127 | 127 | 129 | 129 |

| 80 | 48 | 15 | 22 | 142 | 142 | 144 | 144 |

| 100 | 72 | 15 | 24 | 162 | 168 | 170 | 170 |

| 125 | 95 | 16 | 26 | 190 | 192 | 186 | 186 |

| 150 | 115 | 19 | 29 | 218 | 220 | 226 | 226 |

| 200 | 140 | 29 | 43 | 272 | 272 | 286 | 293 |

| 250 | 190 | 29 | 43 | 327 | 330 | 343 | 355 |

| 300 | 218 | 38 | 50 | 378 | 384 | 403 | 420 |

- Main size and weight

| Dn(mm) | 1.0 | 1.6 | 2.5 | 4.0 | 6.3(6.4) | 10.0 | 16.0 | |||||||||||||||

| (mm) | (kg) | (mm) | (kg) | (mm) | (kg) | (mm) | (kg) | (mm) | (kg) | (mm) | (kg) | (mm) | (kg) | |||||||||

| L | D | L | D | L | D | L | D | L | D | L | D | L | D1 | D2 | ||||||||

| 50 | 60 | 109 | 2 | 60 | 109 | 2 | 60 | 109 | 2 | 60 | 109 | 3.5 | 60 | 115 | 3.5 | 60 | 122 | 4 | 70 | 143 | 122 | 6.5 |

| 65 | 67 | 129 | 3 | 67 | 129 | 3 | 67 | 129 | 3 | 67 | 129 | 5 | 67 | 140 | 5 | 67 | 147 | 6 | 83 | 163 | 147 | 9 |

| 80 | 73 | 144 | 4 | 73 | 144 | 4 | 73 | 144 | 4 | 73 | 144 | 7 | 76 | 150 | 7 | 73 | 157 | 8 | 83 | 178 | 157 | 14 |

| 100 | 73 | 164 | 6 | 73 | 164 | 6 | 73 | 170 | 6 | 73 | 170 | 9 | 79 | 177 | 11 | 79 | 183 | 12 | 102 | 210 | 183 | 24 |

| 125 | 86 | 194 | 7.5 | 86 | 194 | 7.5 | 86 | 197 | 9 | 86 | 197 | 16 | 105 | 213 | 20 | 105 | 220 | 21 | 110 | 249 | 220 | 30 |

| 200 | 127 | 275 | 20 | 127 | 275 | 20 | 127 | 287 | 22 | 127 | 293 | 30 | 165 | 313 | 41 | 165 | 324 | 46 | 206 | 358 | 324 | 55 |

| 250 | 146 | 330 | 30 | 146 | 332 | 32 | 146 | 343 | 38 | 146 | 355 | 80 | 213 | 364 | 70 | 213 | 394 | 76 | ||||

| 300 | 181 | 380 | 48 | 181 | 387 | 50 | 181 | 403 | 54 | 184 | 450 | 86 | 229 | 424 | 100 | 229 | 458 | 110 | ||||

Enlarge Image

Enlarge Image